Back to my work

3D Modeling

3D Rendering

Scope

Thesis project

Institution

University of Málaga

Role

Mechanical Engineer

Year

2020

Purpose and Research

The goal of my Mechanical Engineering thesis is to improve the quality of life for patients undergoing rehabilitation following finger surgery, typically due to injuries such as cuts. Thanks to the help and guidance of my professor Alex Bataller, we developed an active splint to address this need.

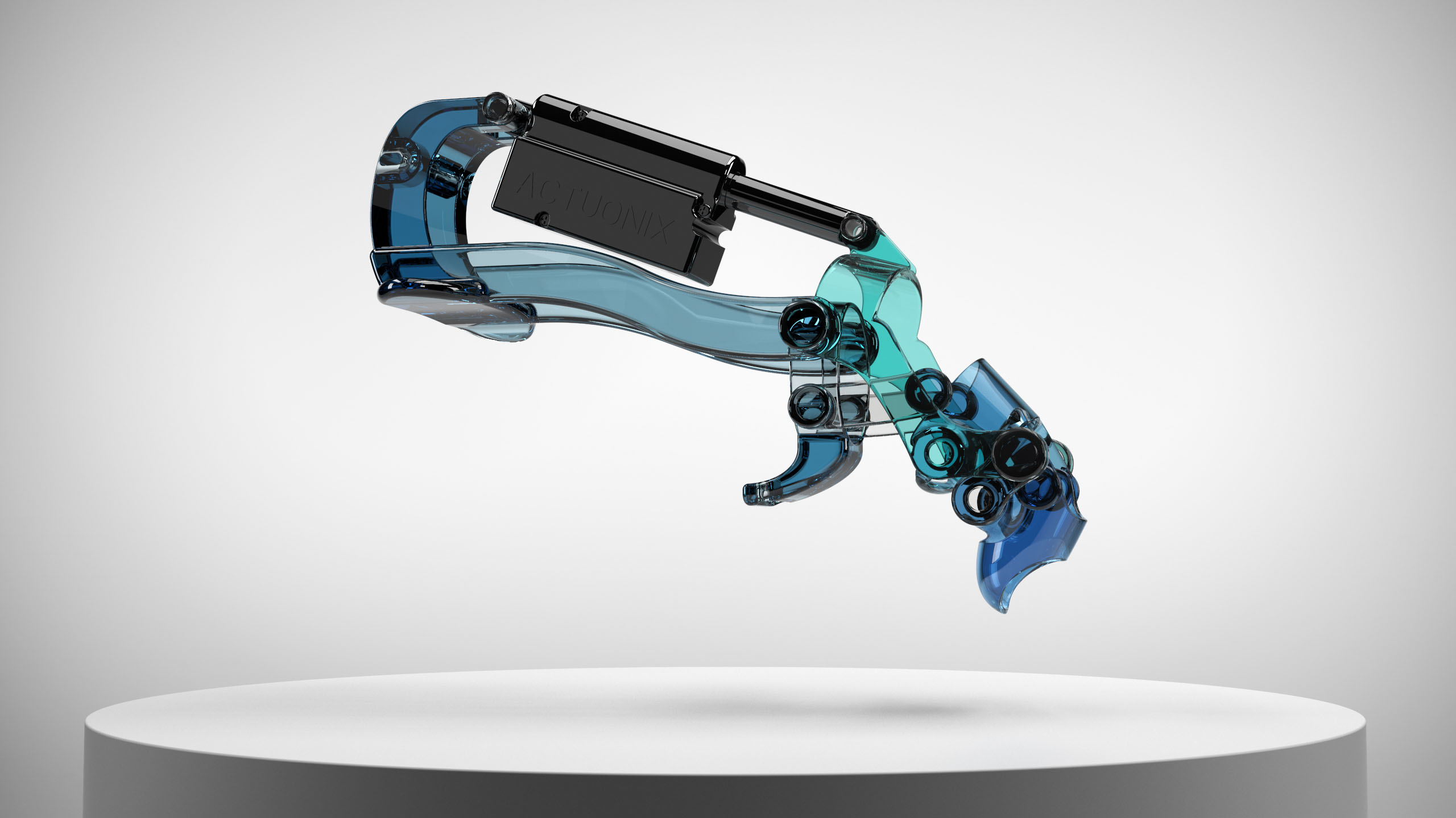

This project focuses on designing and manufacturing an active splint that offers ergonomic, lightweight, and comfortable support for the patient's hand during recovery. Additionally, it is cost-effective, thanks to utilizing 3D printing technology. Active splints facilitate joint mobilization within the flexion-extension range, aiding in restoring muscle balance in the finger.

To ensure versatility and customization for each patient, the splint model is entirely parameterized using SolidWorks. The rendering process was completed using KeyShot.

-

Throughout the rehabilitation process, it's crucial that the finger only moves within the parameters set by the splint. Any unintended movement can impede the recovery process.

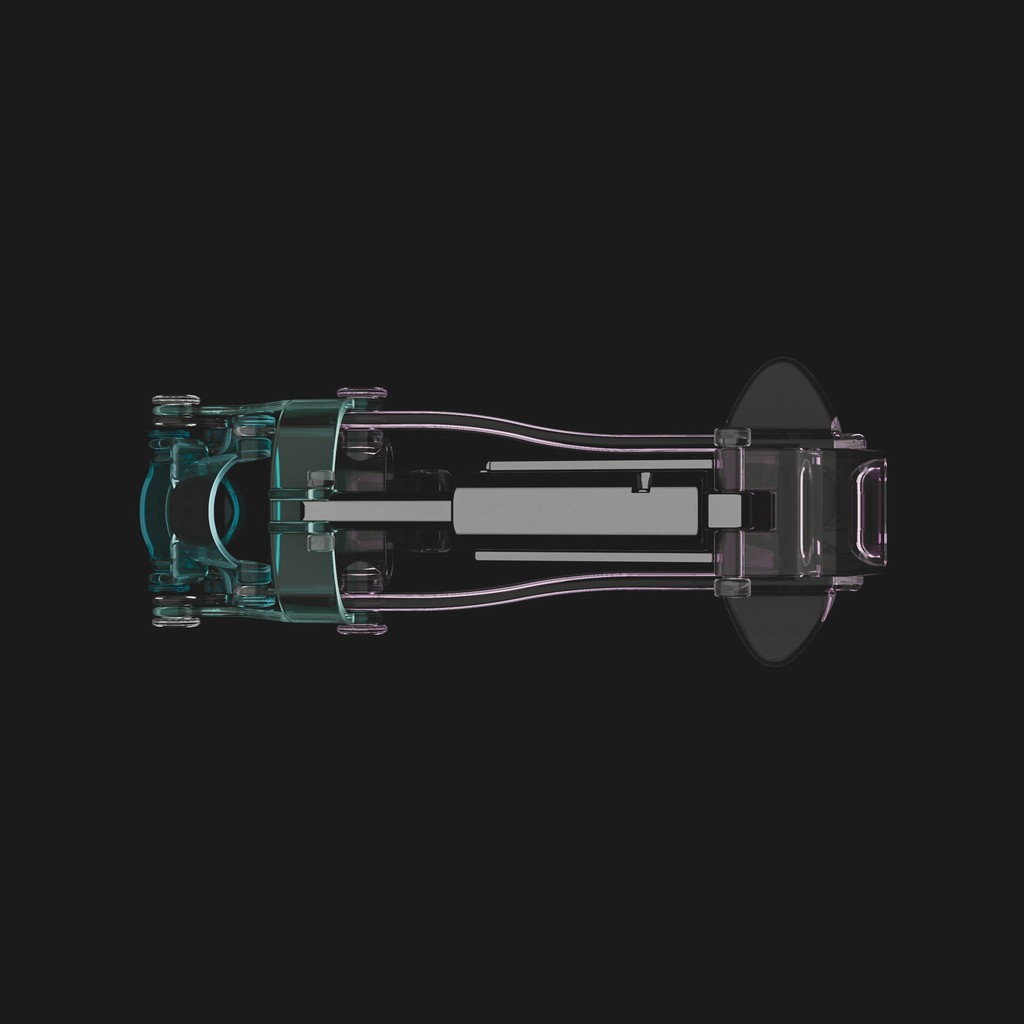

The splint incorporates a linear motor to facilitate controlled flexion and extension of the joint when the patient wears it. Otherwise, the splint immobilizes the finger when the motor is inactive.

-

-

3D Printing

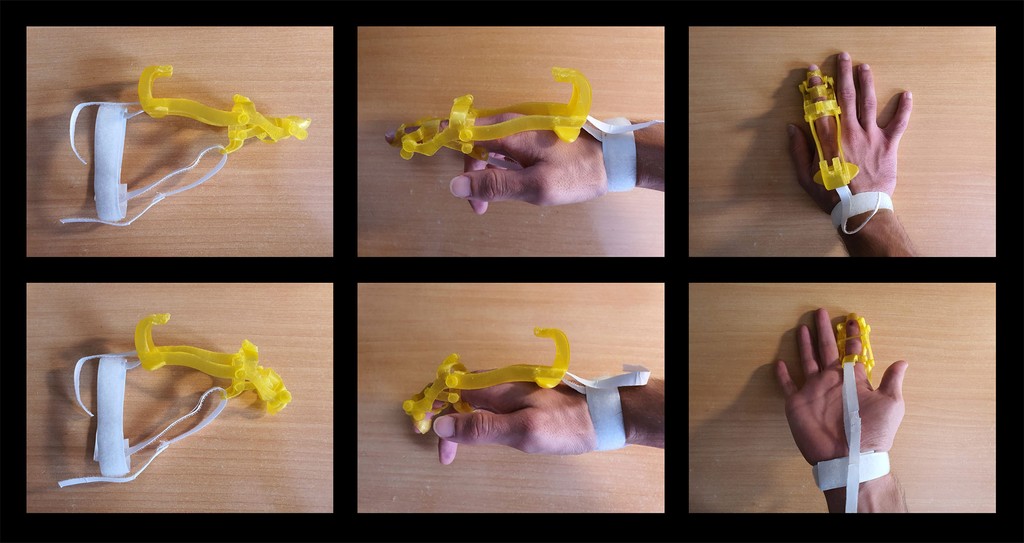

3D printing is part of the foundations of this project, facilitating the testing of various splint components and the entire assembly across multiple iterative phases within the 3D design process. This establishes a validation system for the model.

Excluding the costs of the control system, 3D printing enables the creation of this device at a cost of approximately just 50 cents. The benefits this prototyping method offers to the medical sector are evident.

What's most interesting and distinctive about this design is its ability to be entirely 3D printed in a single print, eliminating the necessity of adding screws or connections between parts afterward. This achievement was made possible by carefully considering the required tolerances in the joints and designing them with cylindrical connections.

To ensure secure fastening, a wristband with two velcro straps enhances the effectiveness of the fit between the splint and the hand.

How does the patient incorporate the use of this device into the rehabilitation process?

This is achieved through the application of Continuous Passive Motion Therapy (CPM). Its goal is to facilitate recovery to a level that allows patients to maintain their regular activities, thereby reducing pain and increasing range of motion (ROM).

Furthermore, it has been demonstrated that this therapy helps prevent the development of edema or blood clots resulting from immobilization of the affected joint post-surgery. It's important to note that the therapy is applied in alternating periods of time (4 hours of use, 4 hours of rest, 4 hours of use, and so on).